Northeast Resource Group, Inc.

Northeast Resource Group, Inc.

PO Box 6294, Plymouth, MA 02362

Transformer Load and Performance Testing

When we perform an initial facility audit to determine the cost/benefit of a potential transformer retrofit, we consider all existing transformers that are 30 kVa and larger for downsizing, especially ones installed before January 2007. Any existing transformers that have the NEMA TP1 (Energy Star) label are still considered, if built before January 2010 as they are not as efficient as ones meeting the new DOE 2016 standard. The efficiency of most transformers is published by the manufacturer making it a straightforward process to compare the operating costs to a new High Efficiency transformers meeting the 2016 DOE efficiency standard.

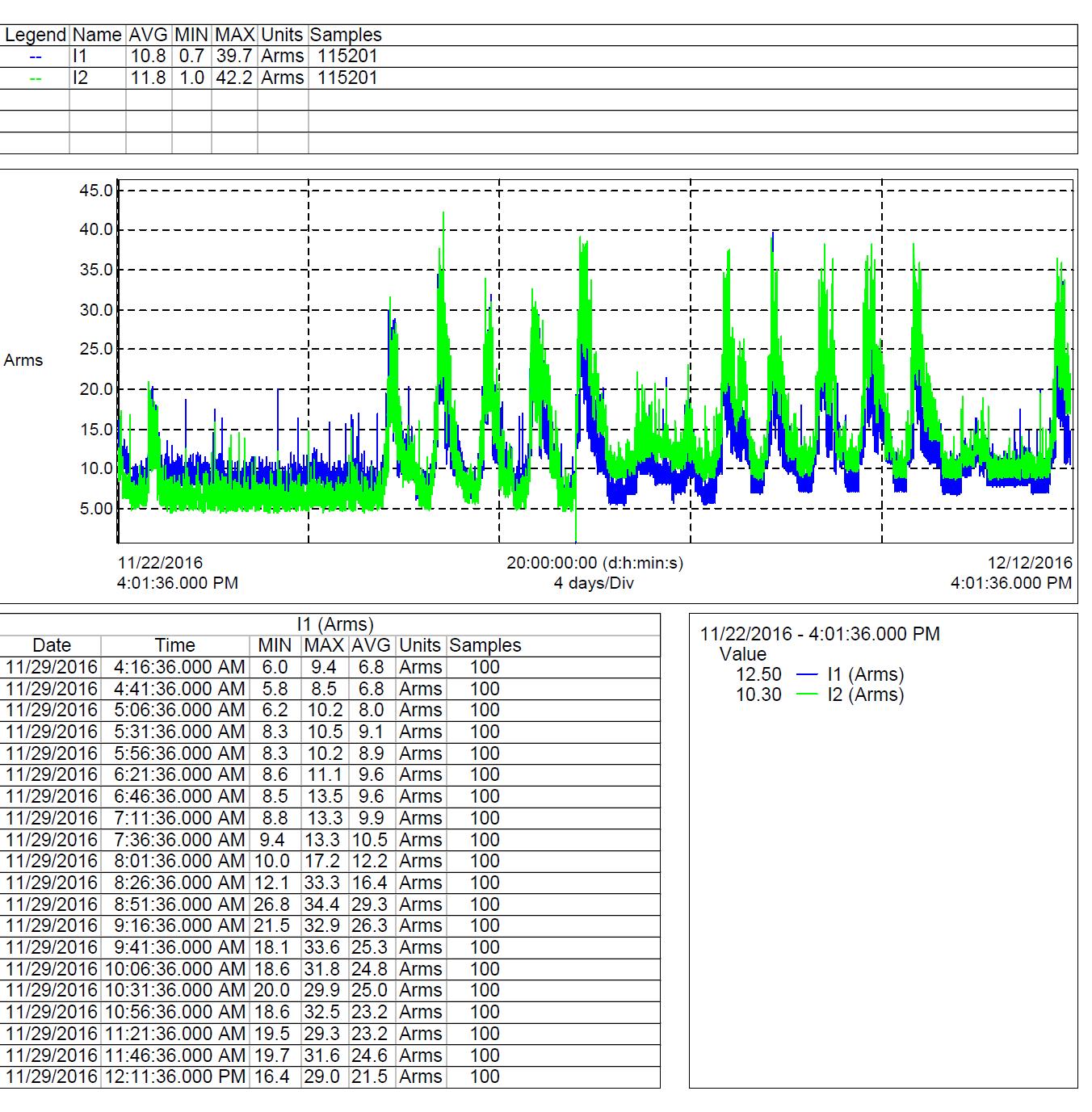

Transformers are often over-sized for their actual load the day they were originally installed and have become more oversize do to efficiency gains over the years. Studies have been performed including one by the department of energy (DOE) which determined average transformer loading across many types of applications such as manufacturing, offices, medical facilities and schools. These studies included actual long term load testing performed, then the results averaged in each of the above use categories. We use these average load profiles to calculate savings on each transformer targeted for retrofit. If we suspect a very over-sized transformer, we can provide a two week load test to determine if downsizing the transformer makes sense. Transformers no load losses are proportionate to its size, the larger the transformer the more it costs to operate even under no load. So a transformer sized more closely to its actual peak load will save additional kWHs. Utility companies such as Eversource and National Grid recognize this and offer rebates to proactively replace less efficient transformers, especially over-sized units. Here is a link to a related paper by National Grid called Transformer Replacement Program.

Our initial on-site audit is performed to determine the existing transformers’ efficiency based on the above and calculate KWh reduction if retrofitted with a like-sized or smaller unit meeting the DOE 2016 standard. It is also necessary for us to consider the current NEC (National Electrical Code) rules to calculate the installation cost to retrofit each transformer as the “code” has likely changed since the existing transformers were installed and we need to meet the new requirements.

Power Factor Correction Analysis

Power factor is a measure of how effectively you are using electricity. Various types of power are at work to provide us with electrical energy. Many electrical utilities charge additional fees for users operating with a low power factor. The New England area has some of the most expensive penalties for low power factor in the country, but many other areas do as well.

We specialize in analyzing utility invoice data to determine if you are paying an additional cost for low power factor and, if so, how much and the best way to correct it.

We have a special website dedicated to help explain Power Factor Correction and how we can help.

Please click here for the link to our Epowerfactor website

Infrared Preventative Maintenance Service

Infrared radiation is electromagnetic radiation whose wavelengths are greater than those of visible light but shorter than those of microwaves. In its most familiar form, it is radiated heat which can be sensed by our skin, yet cannot be seen by our eyes. In summary, its temperature and its emissivity characterize the infrared emitting properties of an object. All objects, whatever their temperature, emit infrared radiation. The intensity emitted depends upon the fourth power of the absolute temperature of the object. It also depends upon the material property of the object, termed "emissivity". An ideal infrared emitter, said to be a "black-body", has an emissivity of unity. Most objects have emissivities less than unity, and therefore emit less intense infrared radiation than a black-body at the same temperature.

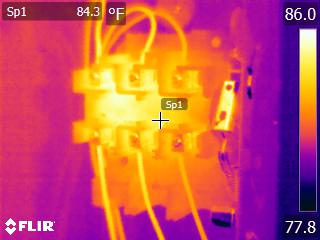

With today's Infrared technology and detecting equipment, we're able to measure very slight thermal deltas between electrical components which can indicate a problem with a component or a termination. A trained person with the right thermal imaging equipment can perform a non invasive, non destructive method of inspecting the condition of your electrical equipment without the need of an electrical shut-down.

We have an experienced team of certified thermographers and electricians with the latest equipment that will perform an inspection of the electrical equipment in your facility for a very competitive cost.

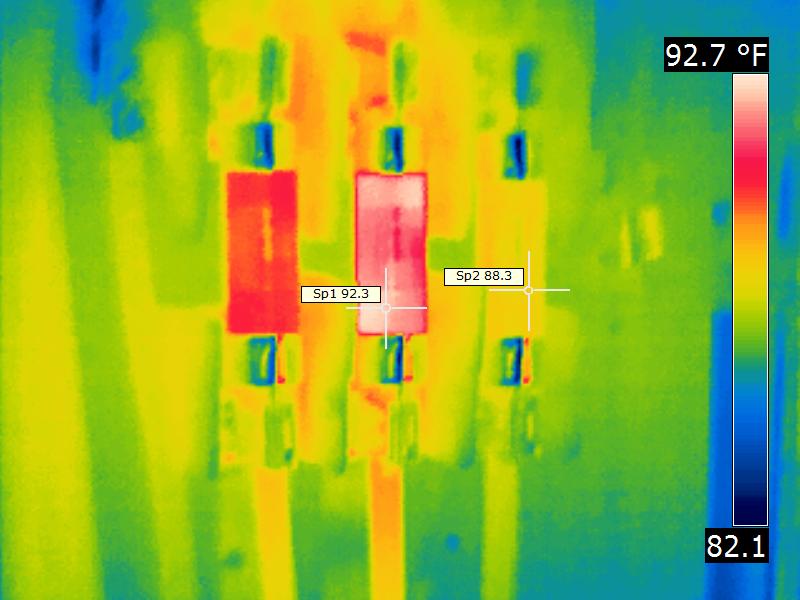

Below is an example of a three phase fused switch with a problem indicated by the thermal delta between fuses.

Please click this link for an example of a report page. EXAMPLE